Specific methods to prevent uneven settlement of steel bellows culverts

2024-04-17

(1) In order to prevent uneven settlement of steel bellows culverts, the construction process of foundation pit excavation and substrate treatment is very important.Before the excavation of the foundation pit, the construction of the ground drainage system should be done well, including the construction of a cut-off ditch around the top of the foundation pit, and the setting of a drainage slope with an outward slope between the top edge of the pit and the cut-off ditch to avoid the instability of the pit wall caused by the flow of ground water into the foundation pit; during excavation, slope excavation or step excavation should be carried out according to the excavation depth of the foundation pit, and the elevation of the bottom of the foundation pit should be strictly controlled to avoid over-digging. When the excavator digs to the bottom of the foundation pit, the design elevation of the base is manually cleaned up, and at the same time, the water collection and drainage pits are set up on both sides of the base to prevent the base There is water that cannot be eliminated in time, causing the substrate to be soaked in water and the bearing capacity to be reduced; the bearing capacity of the foundation must meet the design requirements. When the foundation pit is excavated to the design elevation, a light touch detector is used to detect the bearing capacity of the substrate to determine whether to adopt a reinforcement treatment plan; for areas where the substrate is loose or the water content is too large after excavation, the gravel soil abandoned by the subgrade is used for backfill.

(2) Before the steel bellows are installed, 20cm of well-graded coarse sand is evenly laid on the top of the foundation as a sand cushion, and it is compacted with a 22t vibrating road roller, and the compaction of the sand cushion is greater than 96%.

(3) The place next to the steel bellows is backfilled with coarse sand. The space here is small and can only be compacted by a small rammer. The rough sand in the wedge-shaped part under the pipe is vibrated by a "watertight method" oscillator; the rest of the pipe culvert is layered and backfilled with sifted gravel soil with good water permeability and high strength and small compressibility. The compaction thickness of each layer is controlled at 15cm, and the number of compaction times is determined by on-site tests by test and testing personnel. The compaction degree is greater than 96%, and the on-site construction technicians strictly control the technical indicators in accordance with the requirements, and try to be as large as possible. The compaction of the subgrade of the same section Degree, so that the force of the subgrade pavement after completion is balanced, to prevent post-work settlement.

Keywords:

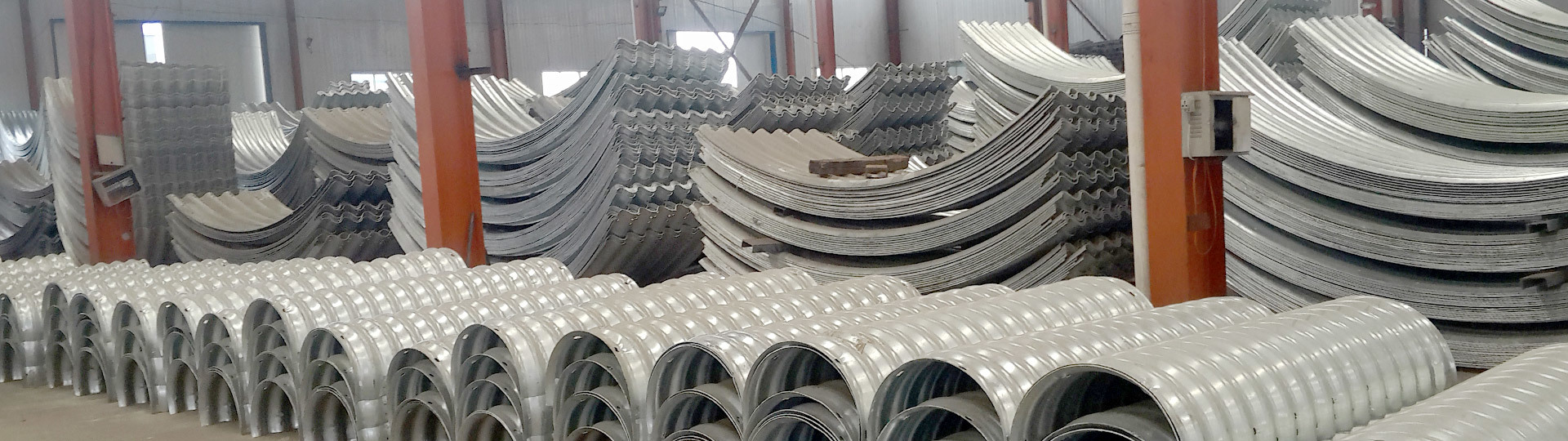

Corrugated Steel Pipe Culvert

Related information

Treatment methods of various soil-based foundations during the installation of steel bellows

2024-04-17

Congratulations to Qijia Group for the successful holding of the 2023 groundbreaking conference

2024-04-17

2024-04-17