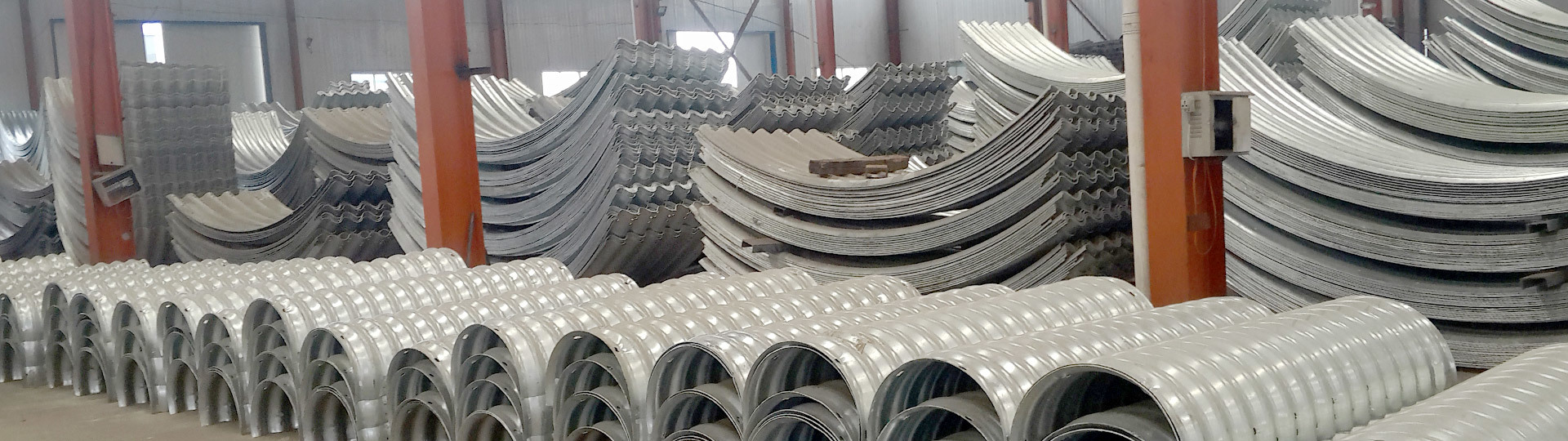

Treatment methods of various soil-based foundations during the installation of steel bellows

2024-04-17

Steel corrugated pipe culverts have the advantages of thin joints, light weight, simple construction technology, and easy on-site installation.In the installation process of steel bellows, the foundation is essential.The foundation should maintain a uniform bearing capacity for the entire steel corrugated pipe culvert, and the foundation where the weak foundation and the rock foundation intersect should be avoided. If it is unavoidable, high-quality sand and gravel should be compacted and formed with a thickness of at least 30 cm to minimize the amount of settlement in the tunnel culvert.This article analyzes and explains the treatment methods of various soil-based foundations during the installation of steel bellows.

(1) High-quality land foundation

Unfiltered sand, gravel, gravel soil and sandy soil are all ideal foundation materials, but hard objects such as stones over 10 cm need to be removed.

(2) General land foundation

For ordinary foundations with small carrying capacity, a foundation of a certain thickness is required.However, if the original soil of the foundation groove of the culvert is strictly compacted (its compaction is 90% of the compactness of the heavy-duty foundation), the bellows can also be directly placed on the foundation.

(3) Rock foundation

Steel bellows cannot be placed directly on rocks or concrete foundation beds. Due to too rigid support, the good flexibility of the pipe wall itself will be continuously reduced, and the carrying capacity of the culvert itself will be reduced. Therefore, part of the soft rock should be dug up for the rock foundation and replaced with a layer of high-quality soil. Generally, it is appropriate to replace it with a thickness of not less than 30 cm, and carefully tamp it down.For digging soft rock trenches, strong explosives and deep-hole cannons cannot be used to avoid too much outer layer being blown loose.The foundation of the rock weathered layer cannot be used as the foundation, and it needs to be replaced with 3D width high-quality soil.

(4) Soft land foundation

When the culvert is on a soft land foundation, the soft land foundation needs to be treated. The treatment method of the culvert foundation is the same as that of the road section, and then a layer of high-quality gravel cushion greater than 30 cm thick is filled on it.

(5) Wet subsidence loess foundation

Due to the particularity of the soil quality of wet-trapping loess, after the foundation pit is excavated, the substrate is backfilled with flake concrete (or 3:7 white and black soil) of not less than 50 cm, and a high-quality gravel cushion with a thickness of 30-80 cm is backfilled on it.

(6) Silt river foundation

In a river channel with flowing water all year round, the silt carrying capacity is poor. The general treatment method is stone throwing. The thickness of the stone throwing is 1.5-3 meters. After stabilizing it, compaction machinery is used to compactor it, and a gravel cushion of not less than 30 cm is laid on it. If the river channel is deposited as a sand and gravel material, the steel corrugated pipe culvert can be directly laid after compaction.

Keywords:

Corrugated Steel Pipe Culvert

Related information

Treatment methods of various soil-based foundations during the installation of steel bellows

2024-04-17

Congratulations to Qijia Group for the successful holding of the 2023 groundbreaking conference

2024-04-17

2024-04-17